- Technologies

- Welding

Our welding procedures

We offer two different welding technologies. WIG welding for UHV-Applications and also laser welding as a farther technology which allows to connect small work pieces. It is possible for us to connect a wide spectrum of materials. If you have any questions, please don’t hesitate to contact us.

|

|

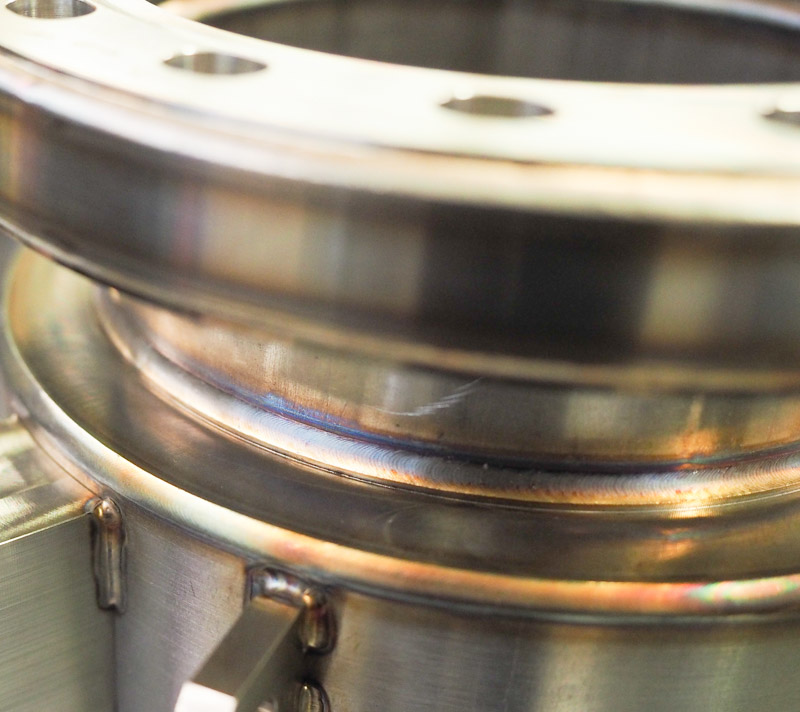

An easy use and a good controllability of the arc allow a very comfortable and clean work with the WIG welding. The narrow weld zone, a low scaling of the work piece and the molding arc provide clean, exact seams without slag inclusions and without reworking. With our WIG welding equipment it is possible for us to weld together parts and assemblies after your provisions. The focus is on fine-mechanical components which are connected by the WIG welding technology. We have years of experience in welding UHV-components. The WIG welding is applied mainly for the welding by high-grade steels, aluminum, titanium and Inconel. |

|

Different components of an assembly are connected with each other by laser welding in the sub-millimeter range. This technology is used in areas in which other welding procedures are not practicable because of the thermal load or the small component size. The technology of the fine laser welding has also proved itself with the component fixing with welding spots. With the help of micro laser welding under microscope almost all metals can be connected reliably and with high precision with each other. |

WIG Welding

WIG Welding